Excavated material is a subject which is often asked about. Iain Phimister, Senior Lead Engineering Manager for Nuclear Waste Services (NWS), attended a Community Partnership meeting and provided explanation. Here, Iain provides an overview of excavated material management for a Geological Disposal Facility (GDF).

A GDF will be a significant piece of UK infrastructure with the majority of the facility built between 200 and 1000 metres underground.

Throughout construction, there will be a substantial amount of material to excavate. How we will manage the material depends on the type of rock we will be tunnelling through. Once the host geology and construction methodology are understood through the analysis of data from our site characterisation process, a detailed material management strategy will be developed.

Currently, we estimate that the total volume of excavated material is approximately 10million cubic metres within the host rock. Additional excavated material will also be produced from the construction of the accessways running from the surface site to the host rock.

Excavated material will be generated through the initial construction works and will continue throughout the ongoing construction and waste emplacement operations. This activity will continue for over a century.

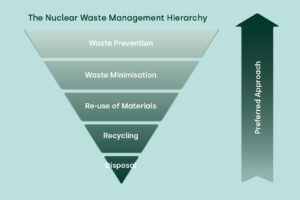

NWS has a sustainability strategy and as such we will apply the waste hierarchy in managing excavated material. Where the generation of excavated material is necessary, our ambition is for sustainable reuse of that material to minimise its transport and disposal to landfill.

It is not possible to prevent excavated material generation for a GDF, but we will seek to minimise the amount of excavation needed through application of good design principles.

All opportunities for reuse of material at the GDF surface site will be considered when we have the information we require to make decisions. Any excavated material retained on site will need to be suitable for use and be available in the quantity required at the time it is needed.

Such uses could include landscaping or visual screening mounds, flood defences or environmental enhancement projects.

Excavated material may also be suitable as a backfill material either as an engineered barrier in the disposal areas or as a mass backfill of other underground tunnels. The radioactive waste and construction materials will occupy a significant portion of the excavated space within the GDF meaning the amount of backfill material needed is less than the excavated material volume, and so only a portion of it could be reused as backfill.

We envisage construction of new disposal areas and backfilling disposal areas already filled with radioactive waste in parallel throughout the life of the GDF, so some freshly excavated material could be used promptly as backfill. All material re-use will be carried out under internationally recognised frameworks for material re-use such as the Definition of Waste-Code of Practice.

For excavated material that cannot be retained and reused onsite we will consider options for recycling offsite as either:

- An engineering material, for instance in road/infrastructure construction.

- A bulk fill material to protect valuable land from flooding/coastal erosion or for habitat creation as demonstrated by other major infrastructure projects.

It is important to recognise that the generation of excavated material will be spread over the construction and operational life of a GDF. As such, if it is transported offsite, any demand on the transport system is expected to be manageable.

Recognising that some material may need to be removed from site, our illustrative design includes export facilities for excavated materials, including rail when connections are available. Our current estimate is that during peak construction the demand on the rail network, if excavated material is promptly removed from the GDF site, is 12 trains of excavated material leaving the GDF site each day.

Our current site evaluation work will further develop our understanding of excavated material in terms of volumes, logistics, and material management options.

Site characterisation works undertaken using boreholes will further help us understand more about the rock and improve our understanding of the quantity and type of excavated material that may be generated and its reuse opportunities.

Case Study: Crossrail

An example of beneficial re-use of excavation material from a major project is on the Crossrail project. Crossrail involved the construction of 42 km of tunnels running from Royal Oak Portal in the west of London, to Pudding Mill Lane portal on the north-east spur and Plumstead portal on the south-east spur and the excavation of boxes, shafts and caverns for associated portals, stations and shafts generating over 7 million tonnes of excavated material.

By the time all the tunnelling, stations and shafts excavation was complete over 98% of the excavated material had been placed at sites for beneficial reuse and a large proportion of that had been used

to create a significant part of one of the largest wildlife habitats in Western Europe. In achieving this, 80% on a tonne per km basis was transported by water or rail without compromising either the tunnelling or any other elements of the construction programme.

At Wallasea Island a wetland nature reserve was created from low quality farmland in collaboration with the Royal Society for the Protection of Birds (RSPB). Clay from the tunnelling in central London was taken by rail and by ship where a special jetty was constructed to allow ships to offload the excavated material. Other chalk materials which were not suitable for use at Wallasea Island were reused elsewhere to cap landfill and to create rare chalk wildflower meadow habitat.

The Wallasea Island wetland area now provides winter grounds for wading birds, as well as breeding areas for birds and aquatic wildlife.